Our mission is to promote education and fellowship through the sharing of information and the promotion of the world's greatest hobby. - Model Railroading.

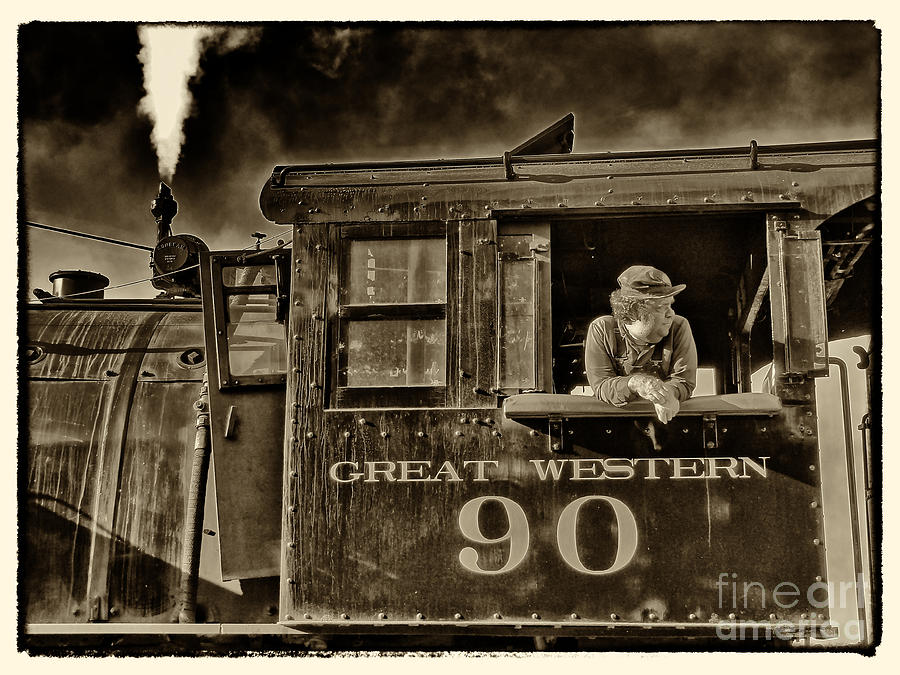

Railroad Item of the Month

Sandy Nelson Layout. Pictures taken @ the 2019 Convention

Paul Marsden

View from the Cab

The last meeting held by the Black Swamp Division was in February. Since the virus hit, we've been waiting and watching, hoping to resume soon. After nine months of this limbo, there is no end in sight and even the best case scenarios make it likely that we will have to scrap our 2020-2021 meeting year. With that gloomy prospect looming over us, there is light at the end of the tunnel! I am pleased to announce that Plan B has arrived: on Friday, November 20, we will hold the first online meeting in our Division history. We've purchased a Zoom license and run some preliminary test meetings to iron out the bugs and take notes to help our members connect successfully. Instructions and details are included in Assistant Superintendent Marshall Stull's column later in this Train Order. We realize that this concept is new to many of you and may be a little intimidating, but please make every effort to connect and we will help you with any issues. I am excited about the meeting agenda and look forward to seeing and talking to you again! Start thinking now about what you can share on Show-n-Tell and check Marshall's comments on how we are going to do it. For this first meeting, we will keep the agenda simple, then add some layers of content as we all get some practice. And here is a bonus: we will have a December online meeting too! Since we can't hold our annual Christmas Party, plan to join us online Friday, December 18. And of course, we will continue this plan monthly in the new year, so watch our website for the schedule. We will be promoting each meeting via the monthly Train Orders as well, so you will get plenty of notice.

The last meeting held by the Black Swamp Division was in February. Since the virus hit, we've been waiting and watching, hoping to resume soon. After nine months of this limbo, there is no end in sight and even the best case scenarios make it likely that we will have to scrap our 2020-2021 meeting year. With that gloomy prospect looming over us, there is light at the end of the tunnel! I am pleased to announce that Plan B has arrived: on Friday, November 20, we will hold the first online meeting in our Division history. We've purchased a Zoom license and run some preliminary test meetings to iron out the bugs and take notes to help our members connect successfully. Instructions and details are included in Assistant Superintendent Marshall Stull's column later in this Train Order. We realize that this concept is new to many of you and may be a little intimidating, but please make every effort to connect and we will help you with any issues. I am excited about the meeting agenda and look forward to seeing and talking to you again! Start thinking now about what you can share on Show-n-Tell and check Marshall's comments on how we are going to do it. For this first meeting, we will keep the agenda simple, then add some layers of content as we all get some practice. And here is a bonus: we will have a December online meeting too! Since we can't hold our annual Christmas Party, plan to join us online Friday, December 18. And of course, we will continue this plan monthly in the new year, so watch our website for the schedule. We will be promoting each meeting via the monthly Train Orders as well, so you will get plenty of notice.

Who knows how long this arrangement will be necessary, so let's make every effort to get involved and make these meetings as successful and enjoyable as possible. Yes, it will be different from what we are used to, but together we can restore fellowship and share excellent modeling content in a variety of formats over the Zoom connection. Log on to this first meeting and I think you will be encouraged and appreciate the possibilities!

Stay well friends, see ya on down the line,

Dave McMullian,

Superintendent

From the Editors Desk

First of, I need to appologize for a couple of mistakes in the last issue. In Clinics Corner, they should have been links, which were missing in the initial push of the Train Order. Also, Marshall told me about the missing image in John Gardner's piece, and I completely forgot to fix it. Both issues have since been fixed, so please go back and check it out last month's Train Order in its full glory.

Thank you for all the pieces for the Train Order. I hope that you have liked the range of stuff, plus the new contributions, I sure have. Please keep them coming.

As has been talked about by Dave, and will be covered by Marshall, Zoom is nothing to be scared of, we have already had a couple of dry runs with the application, and there are people out there who can, and are willing to help to make the whole experience work.

Paul Marsden, Editor

Clinic Corner

Please take a moment and vote on subjects you would like to see in the near future! You can also suggest new subjects! Use our on-line form to provide the feedback we need!

Please take a moment and vote on subjects you would like to see in the near future! You can also suggest new subjects! Use our on-line form to provide the feedback we need!

Zoom Meeting!

We are on track (excuse the pun) to our first Black Swamp Division Zoom Meeting! Before we get into the clinic details, lets talk about how to join the zoom meeting and how zoom works. We want everyone, even those who have never used anything like zoom to feel comfortable with what will happen.

Anyone with a smart phone/device or a computer (Windows/Linux/Mac) can be part of a zoom meeting in just a couple minutes. Zoom works best with a webcam and speakers which most modern laptops and smart devices come with by default. If you do not have a webcam you can still participate but may be limited to just watching.

November 20, 2020 Meeting Link

Below is the invitation with links to join the meeting. Note: the "doors" (or in this case windows) open at 6:30PM so the customary getting acquainting time can occur. We will also be providing pointers on video, cameras, sound and miscellaneous issues. At 7:00PM we will begin the official meeting.

Marshall Stull is inviting you to a scheduled Zoom meeting.

Topic: Black Swamp Division Zoom Meeting Time: Nov 20, 2020 06:30PM-Doors Open, 7:00PM-Meeting Starts Join Zoom Meeting https://zoom.us/j/95798189868?pwd=cC8rVlFYMm4xRGRzd2RyQXhEejFMdz09 Meeting ID: 957 9818 9868 Passcode: 347201

In most cases you should just have to click the link above and if software is required, you will be prompted to download and install. Its OK to click the link ahead of time and test if it connects. You will be in the waiting room until the meeting starts (even if its days away). While there you can test your video, microphone and even select backgrounds.

For Those Not Sure About Using Zoom

Just to make sure no one has any issues joining, I am making myself available to test/play/get rid of butterflies with anyone who wants help. I am available most days between 8Am and 4PM to answer questions and even setup a test meeting so you can try it out. Either call me at 248-817-9328 or e-mail me at mstull@marshallstull.com at least a couple days before the meeting. We will do a test together and make sure you can connect and are comfortable with how it all works. Please do not let this new way stop you from being part of the team!! I am here to help and will gladly take the time to help you feel comfortable.

Agenda for the November 20, 2020 Meeting

With using zoom, we will be changing how the meetings work a little. Right now, the agenda is being kept very simple. Dave will start us out with the usual Division Business. Then we will have some fun and test the power of Zoom by asking those willing to do a "Show and Tell" of what you have been working on.

It has been tradition in recent years, when we return from summer break that we ask everyone to bring something they did over the summer. For this meeting we are asking everyone to hold up for the camera something you have worked on. If it's not something you can hold up, you will be able to share a photo or video through Zoom. Again, if you want to test this ability, I am available!

After Show and Tell, we will welcome Phil Doolittle of the Clinton River Division as the guest clinician. Phil will be giving his clinic on the Evolution of the Steam Locomotive. I have personally seen Phil's clinic and he does a very nice job of not getting over-technical and describe very well the how and why the steam locomotive developed as it did.

Keeping it Simple

As stated before, we will keep it simple for the first meeting. For those who have never been in a live video/audio meeting before, here are a couple tips on proper etiquette to keep those embarrassing moments at bay:

- Try to stay muted until you wish to say something (background noises can be bothersome and embarrassing)

- The chat (private or group) feature can be a great tool to message someone without interrupting the live discussion.

- Remember you are on camera, it is OK, to turn off your video if you need a personal "fix"

- Its best to use an ethernet cord instead of WiFi. If you must use WiFi, please locate yourself as close to the WiFi router as possible for best signal strength.

- Choose a location that has moderate light and clean background. If your computer is robust enough, Zoom allows users to choose custom backgrounds.

- Most importantly, have fun! We are all human, stuff happens...

Additional notices will be sent out before the meeting reminding everyone when and how to join the meeting. As always, feel free to drop an email to me with suggestions and comments to mstull@marshallstull.com

Marshall Stull,

Assistant Superintendent

Greater Pennsylvania Railroad

The Smoken division of the GPR is based on a Model Railroader plan from about 10 years ago. . The era is 1945 to 1950 and uses Pennsy. light to medium steam, with a mixture of early diesels. It is single track, twice around design. with 4 passing tracks, a 4 track yard, engine servicing facility and a 5 track positional staging area.

Presently it is set up for 3 to 4-man operation using a basic card system. There are 13 separate switching points (with 3 more in the works).

The layout was conceived and built in about 5 months using major parts of mountain scenery from a previous layout. It is 16' X 13' with a 3' x 5' extension It uses a basic 1x4 wood frame with 1-1/2' blue foam board attached directly with 3 "screws. All of the elevated structure is also foam board for the risers and road bed. There is no wood used except for the frame. The basic elevation is 42". This makes it kid and Grandpop friendly.

All, the wiring runs behind the fascia and is within 24" reach. All of the switches are preassembled on a section of wood roadbed with the switch machines and all the wiring completed on the work bench and then put in place There are no areas that can't be reached easily.

The local is the coal region of Pennsylvania. The scenery is the typical long mountain ridges of that area. All the mountains and elevations are stacked foam board. Presently there are two towns with a third larger city in the works. I use all the standard scenic products plus all types of dirt, saw dust and stone that I find. The ballast is gray shale, from KY which I grind up. Looks better and glues better. I use GOOP for all the areas that you would normally use plaster. GOOP can be colorized, dries slower and easier to use.

After 70 years of modeling I decided to build a layout small enough to finish, maintain and operate however I have modified that plan slightly. I have all the basics in place but have held back on the fine details as I also discovered I have 2 grand children who are interested in trains.

It will take a couple years and I will have 2 helpers to really finish it off.

by John Gardner Division 1 North Central Region.

AHM kit

The grocery store and the Tap Room Tavern are from an old AHM kit I built as a tween. The grocery store was originally a brown and black swirled psychedelic fright. Painting, redetailing and a new awning helped make this a good mid distance building.

The Tap Room is a neat building that just needed detailing to make an interesting model. The last photo is the 4 AHM buildings in a street row.

by Steve Glass

New Modules

I built 3 new modules for use with the modular club I belong to.

by Steve Kellogg

Ocean Water

I am constructing an ocean port scene on my layout that will replicate Searsport, Maine, around 1950. Searsport sits on Penobscot Bay, a large body that leads to the Atlantic Ocean. For years as I've planned this scene, I puzzled over the best way to create the water. Prototype photos show the pier area as relatively calm, without significant waves, yet having that characteristic low "chop" we see in sheltered ocean settings. I needed the water to "flow" back under a long pier with many pilings and I needed to figure out the best application method and color. In this application, I wanted the water to be opaque rather than clear. Years ago I saw an article about using premixed drywall filler to form water. That got me thinking about wall texturing material, so I decided to experiment.

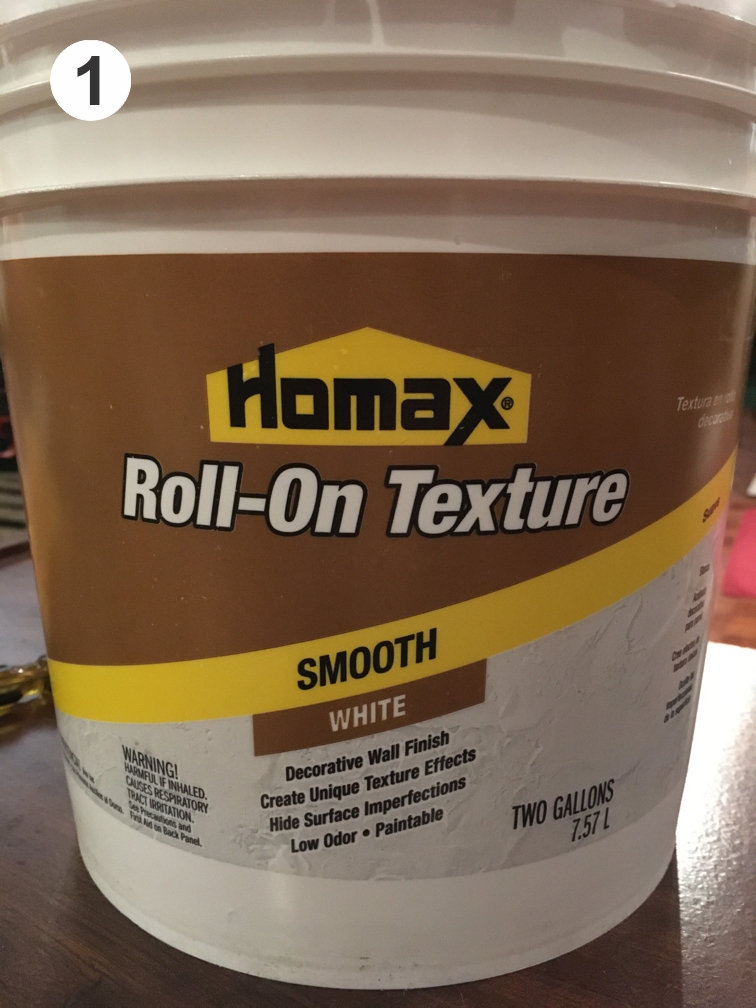

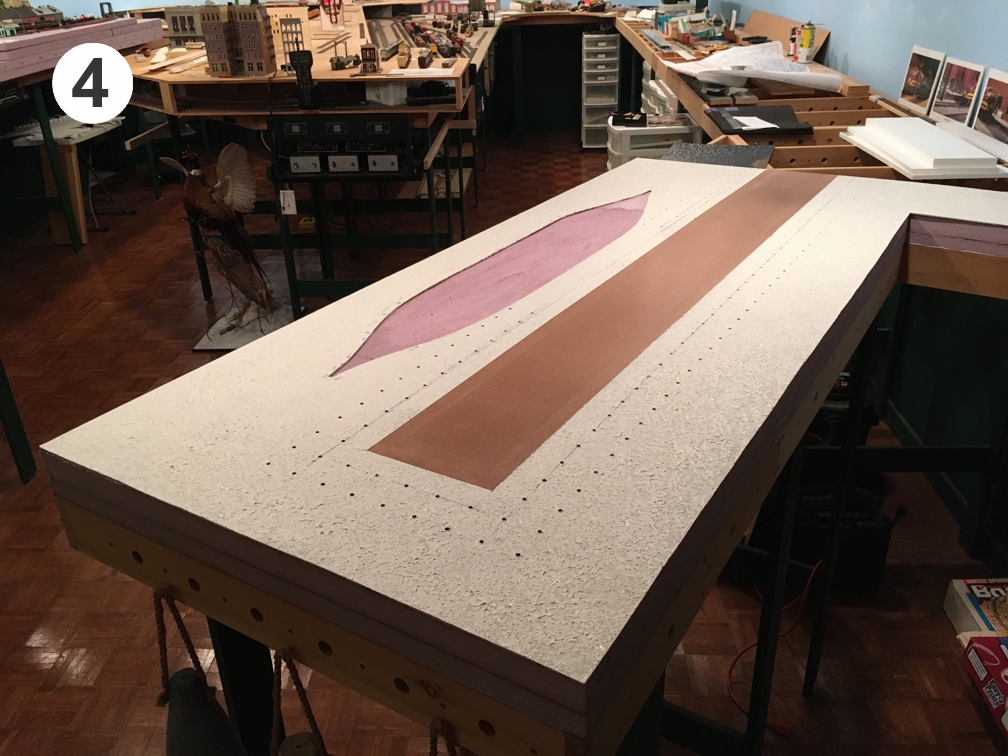

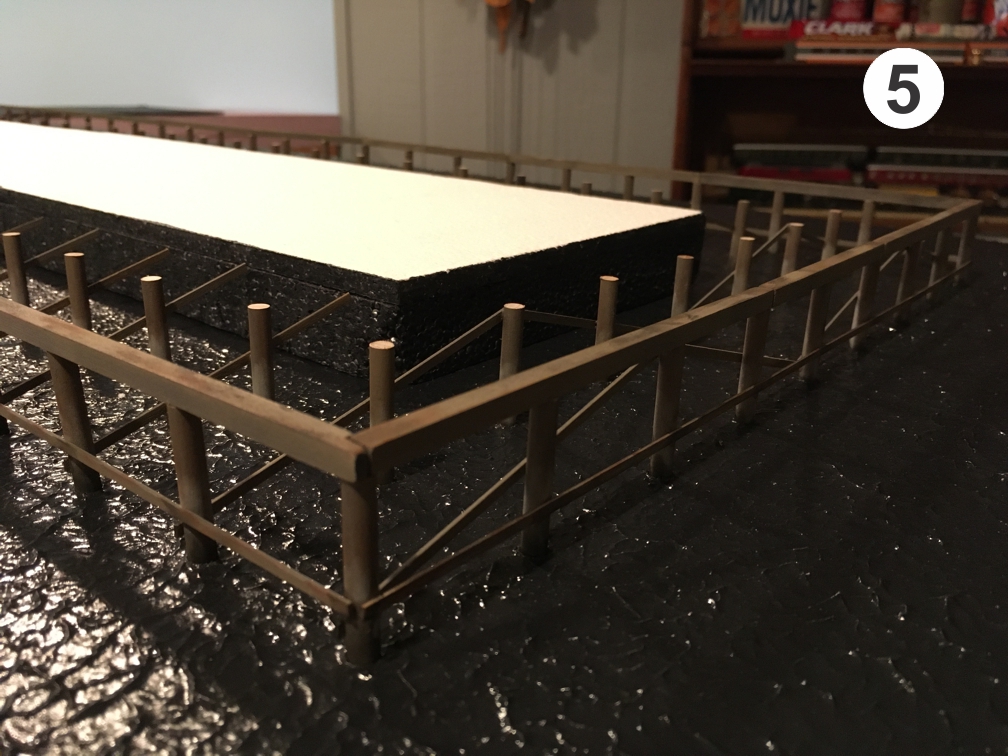

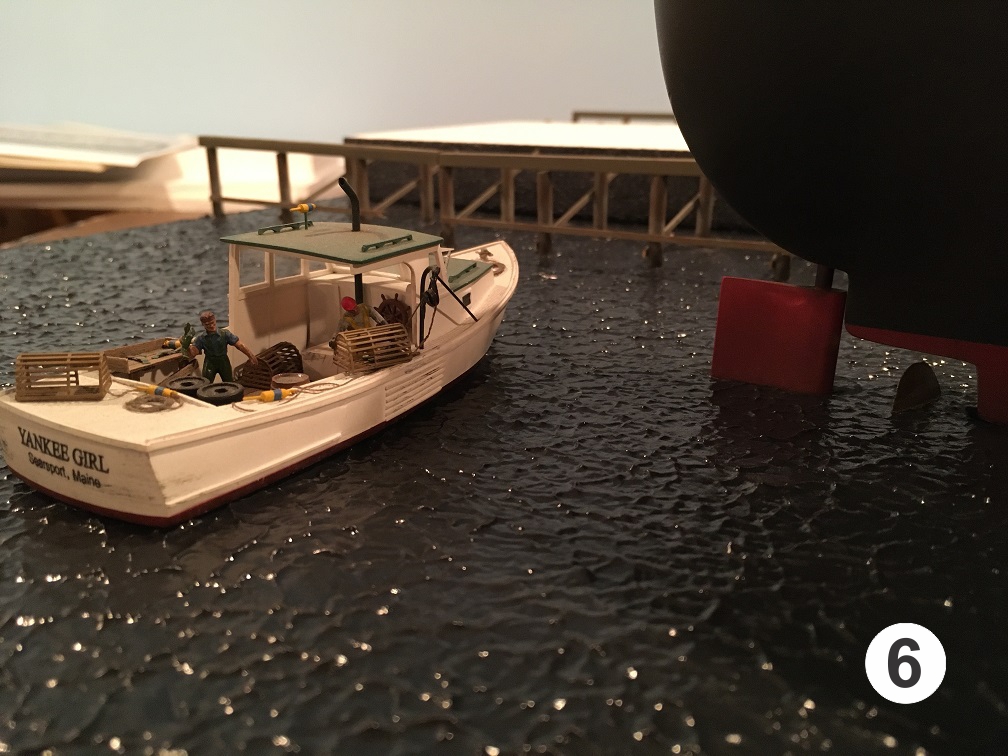

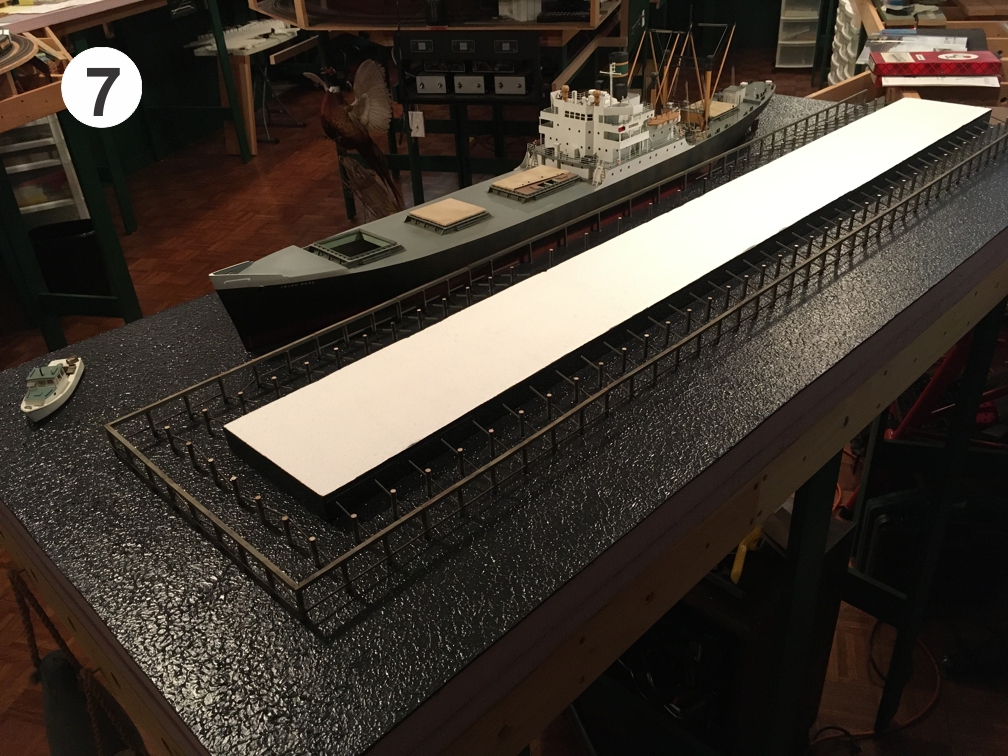

The water foundation is a sheet of 1/8" Masonite, smooth side up, glued to a foam board. Before attaching the Masonite, I carefully cut an opening with a saber saw to allow my ship model to snuggle down and appear to be IN the water rather than ON it. After drilling holes for 170 pier pilings, I was ready to "lay water". Photo 1 shows the material I bought from Home Depot for about $28 bucks. The two gallons will go a long way! While I was there, I also picked up the sea sponge shown in Photo 2. At first, I experimented on a spare piece of Masonite. I glopped a couple of cups of the texture material onto a paint roller pan, then dabbed the sea sponge in and started applying to the Masonite. The best motion was a straight up and down dab without twisting, so that when you lift you form random peaks. By playing around with the amount of material loaded onto the sponge and the amount of strokes, I could control a range of wave heights. The learning curve was very quick, so I went right to work on my pier base! It only took me about twenty minutes to apply the entire area, which measures 6' x 2.5' plus a side extention. Photo 3 shows a closeup of the wave texture while wet. I was pleased that it did not fill my piling holes and after drying, it was easy to clear out the hole edges with a hand-held drill bit. In Photo 4 you can see an overview of the entire application drying. Now it was time to paint. I took three bottles of Ceramcoat craft paint from my drawer: a deep navy, an olive green, and a dark brown. By playing around with mixes of these on a pallette, I came up with a color that looked realistic to me. I smeared some of this on an index card and took it to Home Depot where they scanned and matched it with a quart of Valspar High Gloss Enamel (it's water based for easy cleanup). I had to brush it on slowly as the waves tend to make the paint foam if you go too fast. This paint covered extremely well with only one coat and provided a good shine. However, I wanted as much shine as possible so I painted a test board. I left 1/3 of the paint uncovered, applied acryilic gloss medium to 1/3, and brushed Pledge Floor Care on the remainder. The Pledge was the clear winner so I brushed it over my entire water area, again slowly to prevent bubbles. I am very pleased with the shine but intend to apply a second coat once I finish working on this area.

With everthing dried thoroughly, I continued with construction of the pier pilings and braces. Photos 5, 6, and 7 show how the finished surface appears. As you can see, the small boat looks OK sitting on top of the waves. I glued the tip of the ship's propeller to the finished water using canopy cement, which dries very glossy so you don't have to be too "neat" with it. You could use this same technique to apply buoys, floating objects, or a shark's fin! I have been working on this pier scene for a couple of months now with the water in place and am very impressed with its durability. I found one tiny wave-top nick but a quick touch of paint on a toothpick fixed that. I heartily recommend this method and encourage you to play around with it to achieve other types of surfaces.

Dave McMullian

Dunkirk, Pennsy Tower

Between Findlay and Kenton In little old Dunkirk, there still stands a former Pennsy tower that is in relatively good shape to this day. Most of the windows are boarded up but it does look as though it could go back into service (not likely) with only a minimal amount of work.

Using Walthers brick sheets, Tichy windows, doors & stairs and scraps of strip styrene from the scrap box, I built my version of the tower...

Dan Merkel

If I had ti to do all over again, I would have planned on the stairs & awing differently. I put the awning on, thinking that I could add the vertical supports afterwards but quickly found that there was no easy way to attach them so I went for plan B which was the triangular supports on each end. Otherwise, I think it gives a fairly good presentation of the building. Some members from that area may well recognize the structure...

One thing that I did do that was "different" was to use Tichy framed windows but glue them backwards, inside out and upside down. The regular Tichy masonry windows don't leave much room for error at all.

Classifieds

I will sell to anyone in the division for $15. It is an On3 craftsman kit for two ore cars, less trucks and couplers. The box has been opened but all pieces are there. To purchase send an e-mail to mstull@marshallstull.com and a hand-off will be worked out.

Train Order

Train Order