NCR Black Swamp Division (Div 1) Officers

Superintendent - Marshall Stull Assistant Superintendent - Brian Burr Chief Clerk - Ray Huber Treasurer - Randy Bosscher Trainmaster for Services - Steve Glass Director At Large - David McMullian Director At Large - Tony Kukwa

Appointments and Helpers

AP Program - Ron Gilbert Editor/Webmaster - Marshall Stull AV/Computer Support - Steve Glass AV/Computer Support - Steve Richwine New Member Outreach - Open

We Need Help!

We need stuff for the Train Order! Please submit any article/photo/information to the editor. any kind of information is great, please tell us what you are up to!! Even if it's just a photo of your layout, something you saw, or what's on your worktable we would love to see it.

Sharing is the best way to spread the hobby and ideas.

Our mission is to promote education and fellowship through the sharing of information and the promotion of the world's greatest hobby. - Model Railroading.

From the Editor

Welcome to the Holiday Issue of the Train Order! I have tried to add a little "festive" atmosphere to the Train Order. I hope you enjoy!

For December we have another addition to the "Observations" column by Larry Hickman. Larry has agreed to be a regular contributor with the Observations column. Each month in the column Larry will share his experiences working in the prototype world of railroads and ways to model that world. Please make sure to share feedback with Larry as feedback is always welcome and helps to keep the writing spirit active. Larry also wants to make sure everyone is aware, he is available any time for questions, hints or tips on any model railroad or prototype subject.

I do want to make it clear, just because Larry is providing content, the rest of you are not off the hook!! We still need more! So please, share your adventures in modeling with pictures, words or links to your favorite stuff. Variety is the spice of life!!

WANTED! - Photos and Articles for the Train Order!! New content is always needed, and new thoughts and ideas are the best. Even new twists on old ideas are great. Maybe you have a certain technique for ballast or car maintenance or a locomotive you just upgraded. Send a photo and a small paragraph. It does not need to be professional, just jot it down in an email and fire away. Any content is welcome. Email any content or ideas to the editor at blackswampdiv@div1.ncrnmra.org.

View from the Cab

Welcome to December!

December Holiday Party - We will have our holiday party on December 20, 2024. As decided at the last meeting it will be a pizza party! To make the party as festive as possible we are encouraging people to bring:

- A Treat to Share

- White Elephant Gift Exchange (details on what this is can be found at https://www.whiteelephantrules.com/)

- Holiday Show and Tell Item

Again, the party will be on Dec 20th at the Proclaim FM Community Center, 7112 Angola Road, Holland, OH. This is the same location as our monthly meetings. Doors Open at 6:00PM and Food is Served at 7:00PM

Modeling Challenge! - The kits are in your hands now! Some I am sure have already started while some others (like me) are procrastinating, err I mean, Evaluating Build Options. For those who have started, please consider giving an update at the January meeting as part of Show and Tell. it will be interesting to see how people are getting along with the models. Once again, I remind everyone - THIS IS NOT A CONTEST!! This is for fun, to learn, and push our skills.

Make sure to check out Bar Mills' YouTube channel (https://www.youtube.com/@barmillsmodels) for great tips on building their kits.

MOVE TO SECOND FRIDAY MEETINGS - Starting in January 2025, we will be moving our meetings to the second Friday of the month. WHY?? Because the last Friday of the month has not been working. In the past year, we have had to move our meetings four times to avoid holidays or other events. When we looked at the calendar for 2025, we found that the second Friday almost never falls on a holiday. The following is the schedule for Spring 2025:

- Jan 10, 2025

- Feb 14, 2025

- Mar 14, 2025

- Apr 11, 2025

January Open House - We are in need of a layout for our Saturday January 11 open House. if you would like to volunteer for January (or February, March or April) please let me know.

I look forward to seeing everyone at the meeting!

Marshall Stull,

mstull@marshallstull.com

Superintendent

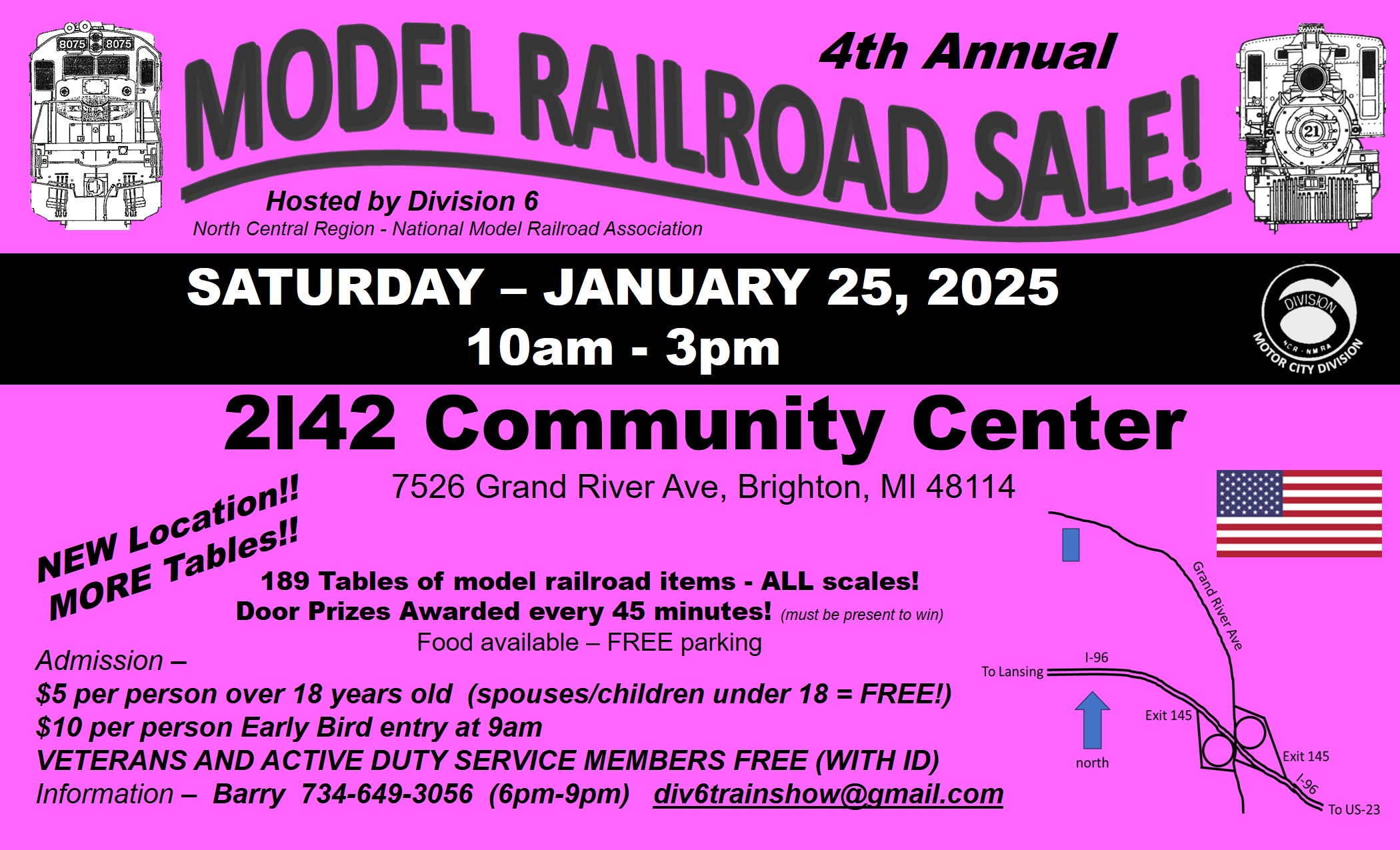

The lighter side of the hobby

November Meeting Highlights

The following items were brought for Show and Tell in November;

Jim West Jim West made a presentation showing how he used LEDs to light ship models he has on his layout and his modules. Nicely done! Jim also had questions concerning the ability to brighten/dim numerous LED lights using a variable resistor and a 12 volt power supply. Many suggestions were made by the Membership. We look forward to hearing what solutions worked best.

Steve Kellogg showed us a model of a DC-3 he built that was once used by the Santa Fe railroad when they offered flight service in the early 1940's. If I understood correctly, the Gov't shut the service down in 1948 because they were a surface transportation company and can't be both. Steve also displayed an old newspaper article depicting former member Ed Gould's layout (circa 1970's - 1980's) and how the Hobby helped with retirement.

Tony Kukwa displayed numerous freight cars that he has rescued and revitalized with new paint schemes and detail. Of note, he had some box cars celebrating the 60th anniversary of the Lake Shore Limited RR and some reworked hopper cars depicting the Detroit Edison fleet of quick dump hopper cars. All nicely done!

Dave McMullian showed us the results of trying a new paint designed specifically for a "metallic look". He applied it to a new locomotive he is working on and the results look, very metallic! The paint is labeled as - Alclad II. According to Dave, the paint is very easy to work with and covers well.

Randy Boscher displayed the end piece for modular bench work that was cut using PNC technology that all but eliminates misalignments when joining modules together. These can be made to your specs and special order - contact Randy Boscher for more information.

OBSERVATIONS - by Larry Hickman

Railroads are divided into regions or districts and are controlled through Superintendents. Locations where yards reside within his district are called Terminals. These are controlled by Terminal Superintendents and his assistants such as Road Foreman and Trainmasters. Every department within these terminals reports to this superintendent such as Car Department, Maintenance of Way, Transportation, Mechanical, Yardmasters and Clerks as well as others not named. Residing within these terminals are yards. What is a yard? They come in various sizes from two to three tracks to as many as fifty or more, where trains arrive, switched and depart on other trains. This is basically what yards do. I've been in major yards from Conway, Pennsylvania to Cleveland, Detroit, Elkhart, Chicago, Columbus, Toledo and Crestline, Ohio. In larger cities railroads will have a major yard and also one or two satellite yards handling local or industrial switching. Major yards are usually divided between two yardmasters, where one end is controlled by one yardmaster and the other end by another yardmaster. Larger yards will be divided into smaller yards, within these larger yards such as Classification, Hump, Arrival, Departure, Shop, Engine Facility and Maintenance of Way. I am not familiar with yards that handle passenger trains, so I will only explain about freight yards.

When trains arrive within yard limits they usually leave the main track at some location and may or may not use a Running Track leading onto a yard lead at Restrictive Speed. Restrictive Speed according to the rules is not exceeding 15 mph prepared to stop short of train, obstruction or switch not properly lined and to look out for broken rail. Before going into the Arrival or Receiving Yard on some railroads the crew would call the yardmaster for a track assignment. In the early years this was handled through a block phone and later through radios. Once the crew received their track assignment the head brakeman would walk the yard lead lining all the switches pertaining to the movement into the assign track. When I left in 2007 a Utility Man would be assigned to handle lining up the route and notify the crew when the train cleared the yard lead into their assigned track.

When the proper switch was thrown, he would board the engine and the train would enter the assigned track ringing the bell as the train moved through the yard. This would let Car Department Employees working on adjacent tracks to be aware of moving equipment approaching their location. Trains unable to fit into a single track would double the headend to an adjacent or another yard track. When the caboose cleared the yard lead and entered the assigned track. The conductor would set the airbrakes by using the caboose valve or whistle and in some cases the radio to stop the movement. In modern times a Utility Man would attach themselves to a crew and help with the double. Once attached to a crew a Utility Man could only work with that crew, until they released themselves and work for another crew. After yarding the train a call was made to the yardmaster for a route through the yard to the engine house. Upon arriving at the engine house the engineer would call the Enginehouse Foreman for permission to enter the Inbound Track. Once granted the engines entered and stopped at a designated location, where the engine handbrakes were applied and the headend crew walked to the yard office if it was close or transportation was called to take the crew to the yard office. At this location they marked off their timeslips and went home.

Once the train was yarded a call was made to the Car Foreman Office by the yardmaster. From this location Car Inspector were dispatched to both ends of the yarded train. In the early years Car Inspectors had their own shanties at each end of the yard. In later years they would arrive by truck from the foreman's office, with one inspector being dropped off at the rear of the train, while the other drove to the front. A blue flag was positioned on both ends of the track during daylight hours and at night a blue light was attached to the blue flag to denote Car Inspectors were on and around this track. Once a track was blue flagged each car inspector would start walking the yarded train checking for defects as they bleed the airbrakes from each car using a bleed rod located on the side of the car. Arriving somewhere in the middle they returned checking the opposite side, until the process was complete. Once they cleared the track the blue flags were taken down. The Car Foreman notified the yardmaster the track was ready for switching.

In the early years a clerk would walk the train and write down car initials and number on their pads. This was done in all types of weather. At the beginning of the Penn Central era clerks would sit in a vehicle at a road crossing and do this as the train pulled into the yard. Later this was accomplished by cameras located at various areas allowing the clerk to roll back the video to see this information. When the conductor arrived at the yard office the waybills were taken to the Waybill Office, where they were matched to the list of the train by the clerks. Once this was done a switchlist was made out and given to a yard crew.

Today's railroading has the conductor holding a small handheld computer to enter data about his train. This was sent to a Data Center showing the train arriving and when ready the Data Center sends a switchlist to the yardmaster, where this is sent to a yard conductor doing the switching or in later years yard foreman on CSX. In the years before the Federal Hours of Service Law crews stayed on their trains from their initial terminal, until arriving at their final terminal. No matter how long it may take. When I started working a typical road day was sixteen hours, this was later changed to fourteen hours and still later twelve hours. This meant you could work up to this time and many times we did. It also stated if you worked over this time period you had to be off work for at least ten hours. There were many times we worked over these times as these old conductors would show out of service at fifteen hours and fifty nine minutes allowing them to return to their jobs in eight hours instead of ten. They would complain the railroad was taking money out of their pockets as the hours of service time decreased. Today you can't do this as a computer tracks everything, back then everything was on paper.

Depending upon the yard you may find a Hump Yard or Flat Switching Yard or in some cases both within a major yard. Each handled switching, but in different ways. Let's talk about flat switching first. In the early years before computers a clerk would arrive at a location with switchlists for each track to be switched. Each list shows car initial, car number, track destination and whether the car was empty or loaded. When flat switching engines can only handle so many cars at one time. A crew member would cut behind so many cars for easy handling, until each cut of cars had been switched. Each crew member would have a copy of this switchlist and position themselves at various locations along the yard lead. The engines would pull out a cut of cars and signal the engineer to back up as the conductor would pull the cut levers on various cuts of cars. As the cars rolled down the yard lead each crew member would move from switch to switch lining up the assigned track and as each car cleared the switch, it was relined and they moved to the next switch. It was not unusual to see three or four cuts of cars rolling down the lead into their various alleys.

When I hired out everything was handled through hand signals, with each signal having a different meaning. There were hand signals for everything and whoa be the poor brakeman who didn't understand these signals. As he would soon find himself getting a good old fashion a--chewing. I know as this happened to me, so I learned these as soon as possible. In later years radios came into play, but many conductors still used hand signals as much as possible because of radio traffic. Many crews could switch two to three trains during their trick or work day. Cars for each destination or block were pulled from the various yard tracks and spotted onto a Departure Track and spotted at the ground air. The train was worked by the Car Department as I explained in the last article. Today this is done by one or two men using a remote controlled operated engine using a control pack to operate an engine. A zone would be set up and the crew switched and spotted cars within this zone. No other crews or trains could enter this zone, without permission of the RCO operator or until the zone was taken down.

I will use Stanley Yard as an example. Hump Yards are different as they use a hill for switching cars. In the early years everything was handled through hump signals. The engineer would watch these signals, which were positioned at various intervals in the Receiving Yard. These signals were controlled at the top of the hump by a master signal box using a lever, which relayed each indication by the conductor or brakeman. Each signal indication would mean something. A green indication would be displayed to bring the cars to the top of the hill at around ten mph. As they approached the top, a yellow was displayed and the process of humping cars would begin at two or three mph. A red signal indication would stop the movement and a red over yellow would tell the engineer to back up. An open block line was used between each tower and the hump letting the pin puller know when to stop as needed. When radios were used the conductor would asked the Utility Man for permission to bring the cars to the top of the hill. Green Block would signal the engineer and the tower operators the cars were coming to the top. Later RCO operators handled all of this working through a Utility Man. Cars are pushed from the Receiving Yard to the top of a hill, where the conductor or brakeman would pull the cut lever on various cuts of cars. As the cars rolled off the top of the hill they passed through a system of retarders. These would slow down the speed of the cars as they passed through these retarders by Retarder Operators. These operators were located in various towers and controlled the routing into the various alleys or tracks into the Hump Bowl. This was done by a combination of handles, which controlled the speed and routes through these various towers. Some handles would line switches to various leads, while others handled the retarders for slowing the cars. Each tower and operator handled different leads. Tower A was the first tower and handled every car going to the different leads, while Towers B&C handled the leads going to tracks assigned for different blocks.

Conductors hump cars by a hump list, which was sent to each tower as well as the hump shanty. These were marked according to the various tracks, where cars were assigned. Tower A marked his list for every lead and handled every car coming off the hill, where the other towers only marked their list for the cars coming in their direction. Tower B handled the Ice Track and 1 thru 16, while Tower C handled 17 thru 42.

In larger terminals controlling the routing of each car was handled by one man operating the routes by himself and working with a pin puller. In today railroading humping cars seems to have gone the way of the dinosaurs according to Hunter Harrison, who is now deceased. As all of the major Class 1 railroads went along with this idea, but in some locations the humps were put back into service as flat switching large cuts of cars doesn't always work, unless traffic is rerouted.

I hope this gives you some idea what is involved, with yarding a train and the various types of switching. Later I will describe switching locals and industrial switching. Until next time.

Enjoy the hobby and most of all have fun.

Train Order

Train Order