NCR Black Swamp Division (Div 1) Officers

Superintendent - Marshall Stull Assistant Superintendent - Brian Burr Chief Clerk - Ray Huber Treasurer - Randy Bosscher Trainmaster for Services - Steve Glass Director At Large - David McMullian Director At Large - Tony Kukwa

Appointments and Helpers

AP Program - Ron Gilbert Editor/Webmaster - Marshall Stull AV/Computer Support - Steve Glass AV/Computer Support - Steve Richwine New Member Outreach - Steve Kapela

We Need Help!

We need stuff for the Train Order! Please submit any article/photo/information/news to the editor. any kind of information is great, please tell us what you are up to!! Even if it's just a photo of your layout, something you saw, or what's on your worktable we would love to see it.

Sharing is the best way to spread the hobby and ideas.

Our mission is to promote education and fellowship through the sharing of information and the promotion of the world's greatest hobby. - Model Railroading.

From the Editor

Welcome to April! Easter is here and the warm weather is finally starting to creep in. Did you see what issue number this is? Can you believe issue #100 is upon us?? That's right 100 issues since September 2013 when Ray Huber took over the newsletter. If you check the website (https://div1.ncrnmra.org/train-order/) we actually have all the newsletters all the way back to January 2010 when the first PDF was made available. There are 125 total! It is quite a historical record and I suggest everyone check it out.

This month's newsletter includes a recap of the Spring Meet and the final review of our Bar Mills Build Challenge. Be sure to check out Larry's Observations column as well where he provides a look at prototype RIP tracks. The publication of the Train Order will be suspended until September 2025 as we take our summer break. I am planning a mid-summer edition to recap the National Convention and provide details about our summer outing which should happen sometime in August.

I hope you enjoy this issue of the Train Order!

WANTED! - Photos, Articles, News for the Train Order!! I have seen some of you with layouts at the spring train shows. Why not send a few photos of the layouts and tell others what fun you had! Send a photo and a small paragraph. It does not need to be professional, just jot it down in an email and fire away. Any content is welcome. Email any content, ideas or news to the editor at blackswampdiv@div1.ncrnmra.org.

View from the Cab

Can you believe this? Our membership has risen again!! We are at 78 members as of the March 2025 reports. I like to think we are doing something right. This month I would like to welcome first time new members Jared Bashaw, Larry Darling and Daniel Lynch to the Black Swamp Division.

A lot has happened during March and April. We had the conclusion of our Bar Mills Modeling Challenge and the Spring Meet on April 5th. The April meeting will be the last meeting before our break for the summer. We do have a few house cleaning items to take care of which include Elections and deciding on a location for our summer outing.

Summer Outing - At the April meeting we will decide on the location for our Summer Outing. In February we presented a few ideas/locations for the outing. We also asked for input on other possible locations. This is the final chance! Please come to the meeting (or email me your thoughts) on possible locations. It just has to be railroad oriented! Simple is good and must be able to accommodate about 20-30 people. Past locations included:

- Tour of Div 6 layouts

- Cleveland Roundhouse 2100 Tour

- Michigan Steam Railroading Institute

- Toledo Maritime Museum

Elections - So far, all current board members have agreed to re-run for their current positions and we do not have any challengers at this time. At the April meeting we will vote and decide the 2025-2027 Division 1 board.

National Convention - Station No.VI - The National Convention is fast approaching, and several Division 1 members are involved in helping plan and make the convention a reality. We strongly recommend if you have not been to a convention before, take advantage of this rare opportunity with the convention within driving range. This convention is being billed as a Convention Like No Other. What that means is the NCR has set several goals to make the 2025 convention serve our members and also promote the NMRA to the maximum extent possible. This includes making sure costs are kept very low and most activities are included in the registration price. Do not wait to register! This convention is already turning out to be very popular with over 650 registrants already. So if you want a seat at the any of the multiple activities, I suggest you do not wait and register today!!

I look forward to seeing everyone at the meeting!

Marshall Stull,

mstull@marshallstull.com

Superintendent

Clinic Corner

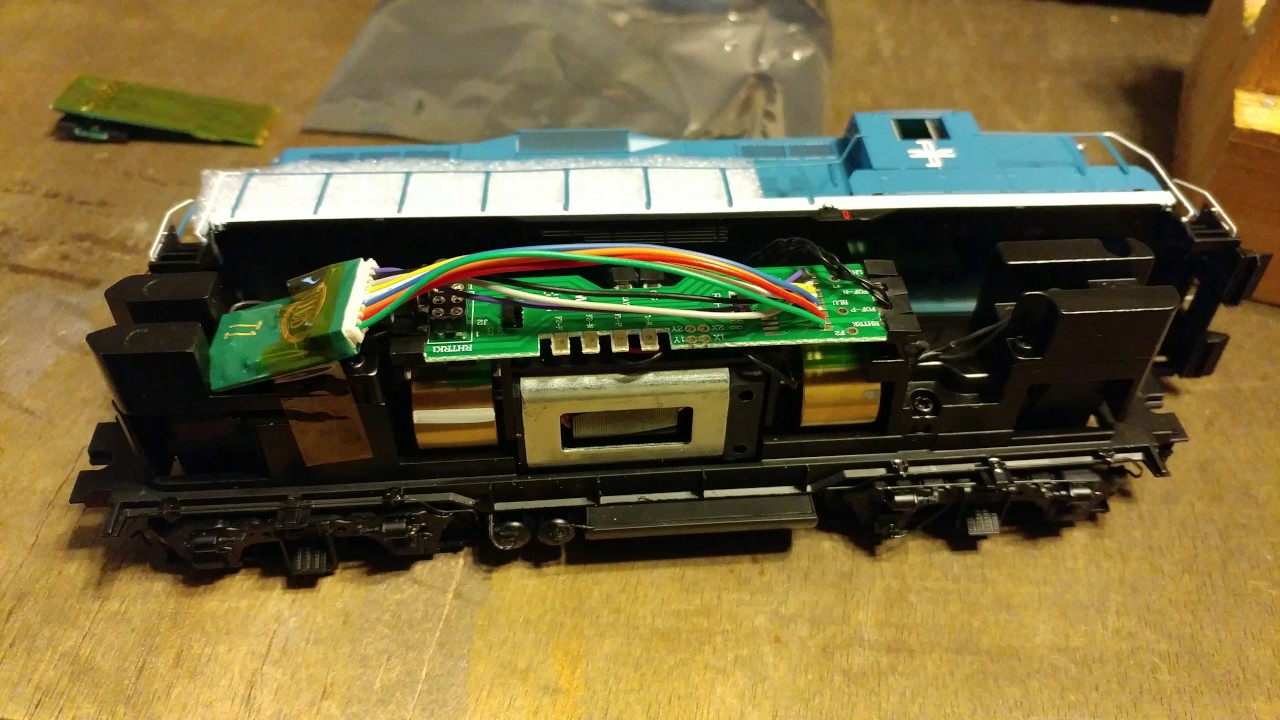

The clinic this month is by Steve Glass and Tony Kukwa. They will be discussing installing different types of DCC decoders in various locomotives. They will have photos and samples to show and will answer questions the audience may have.

See you there,

Brian Burr,

Assistant Superintendent

April 25th Meeting Agenda

Here is a quick breakdown of what to expect at the meeting:

Here is a quick breakdown of what to expect at the meeting:- Rip Track Table - Have items you want to sell or just give away? Put them on the table

- Business

- Q&A - Ask our members about anything

- Show and Tell - other than Bar Mills kits

- Break

- Door Prizes

- Clinic - DCC Decoders

- Closing Remarks - Announcements and Open Discussion Points

The lighter side of the hobby

March Meeting Highlights

The following items were brought for Show and Tell in March;

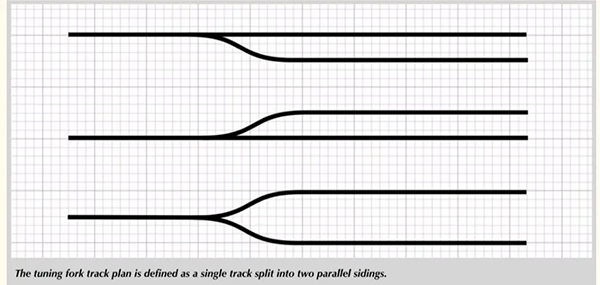

Marshall Stull advised the Membership that a new small layout building challenge was available. It consisted of building a small shelf switching layout with only one turnout allowed. The plan view is to look like a Tuning Fork. Contest information and rules are available at the Micro Railway Cartel Website.

Paul Kemner displayed an old (1972) brass box motor car kit that he plans on building. Looks like a real challenge!

Brad Hicks displayed Pullman Standard PS1 box he built along with the builder photos of that car.

Tony Kukwa displayed some more rescued freight cars.

Dave McMullian displayed a small drill press (6" high) he found on line. Great for small work and has a zero closing chuck with is very helpful when using very fine drill bits.

Randy Boscher displayed a number of items from Nail Supply that he uses as tools for his model building.

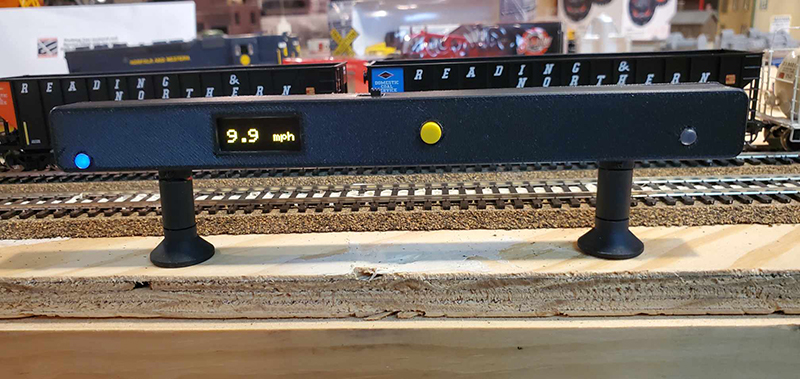

Jim Wolsiffer displayed a speed indicator he purchased.

Larry Hickman displayed a coal tipple he scratch built.

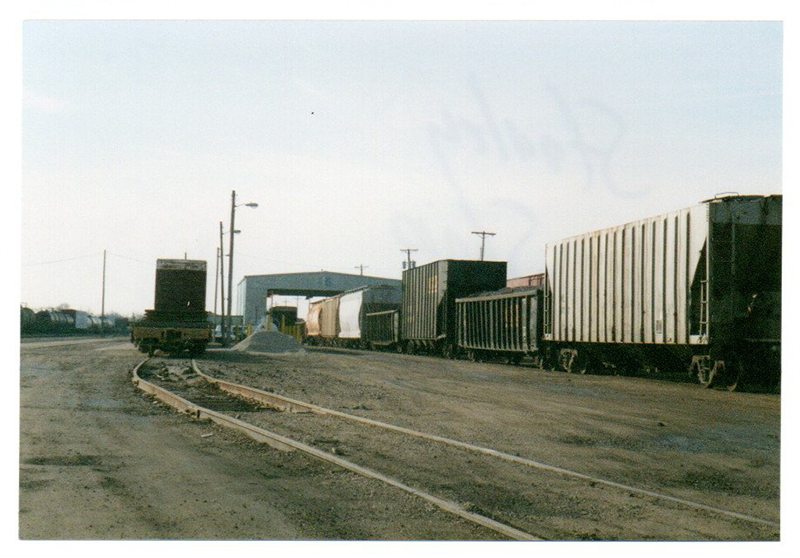

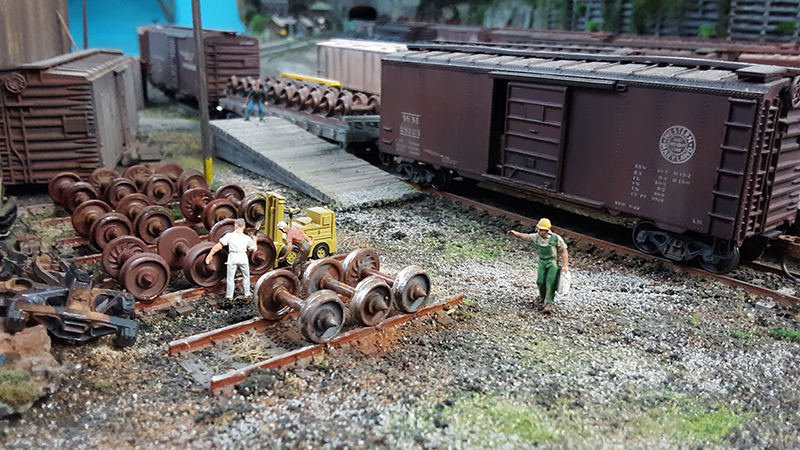

OBSERVATIONS - by Larry Hickman

I would like to explain about RIPs or Repair In Place cars. Most yards or terminals have some type of repair facility, where damaged cars are repaired. At outpost locations this could be as simple as a single track designated as a Rip Track. The local Car Department personnel would have to drive to this location in a company truck and make light running repairs. If the car needed further repairs it would be tagged and transferred to a larger facility, where extensive repairs could be made. In many cases these movements would be handled by a local or at times by a general freight returning back to the nearest yard. If heavy repairs were needed these cars would be handled in a hospital train, where the movement would not exceed 10mph. I've had a few of these and it makes for a very long day.

In cases where a rip(s) had been set out at outlying points and repairs made. A train crew would be notified either by a message from the nearest tower operator in the early years or in later years by radio. Information as to the disposition of the pickup and speed would also be on the message. There were times where a pickup was position on the rear of the train behind the caboose, with a red flag put in the knuckle of the last car denoting the rear of the train. This would depend upon the nature of the repair.

Cars arriving within a terminal requiring more work would be switched from the Receiving Yard and spotted on the shop lead as the train was broken down and switched into various yard tracks for new trains. Repairs were made in the order of the cars importance, which means if the car was carrying hot merchandise it was pushed to the head of the line. I will explain about the Car Shop at Stanley Yard when the yard was still in service as I switched it many times and modeled this shop on my layout.

The shop lead is protected by a blue flag and could only be switched in the evening after the shop personnel went home for the day. The Shop Foreman would send a list of all of the cars to be pulled and any cars not on this list were considered re-spots. Those cars needing emergency repairs were switched from the rip line and positioned under the hood or shop building for the next day. There were some occasions a hot car was pulled during shop hours, but in cases such as these it depended upon the lading and only happened occasionally.

Stanley Shop consisted of two long leads one west and the other east and were divided by a dirt-gravel service road. These leads traveled in a northward direction, with a slight downgrade toward the shop building or hood as it was called. The shop was open ended having no doors and only a roof. The leads continued into and through the building to the opposite side, where it once again tied onto the Ice Track on the north end of the yard. The Ice Track in the early years handled icing refrigerator cars. In later years after refrigerator cars were no longer iced the name stayed. The shop crew for the day was usually one of the hump jobs. A printed switchlist was sent by the yardmaster, where it was relayed to the hump shanty. The appointed crew would be lined into the shop by the Tower B Operator and begin the task of pulling repaired cars and re-spotting rips. The west lead was located next to the Ice Track on the eastside of the Hump Bowl and held all of the damaged cars. Upon arriving the engines were tied onto these cars by the brakeman, while the conductor began walking and checking his switchlist against each car. He also released any handbrakes and removed chunks of wood used as wheel chocks in case of handbrake failure. Arriving at the front of the cars a signal was given to the engineer to stretch the cars making sure everything was together. Now began the slow task of pushing these cars to the shop at walking speed. As the line of cars approached the shop building the movement was stopped. At times you would find a car setting inside the shop hood. This was usually the last car worked before going home for the day. At one time I had a situation, where the list stated it was ok to pull one of these cars. As I began checking I noticed the rear of the car upon off the rails and sitting on wheel stands, with the trucks setting a distance away on the north end of the shop building. A call to the yardmaster to verify my switchlist and needless to say this car wasn't pulled as well as the others on the northside of the building by my crew.

When finding one of these lone cars in the shop and after inspecting for any problems. The car was tied onto the balance and the movement would continue through the shop building, where the outbound repaired cars set. When all the cars were coupled and checked the track was slowly pulled back. Any outbound repaired cars were switched to the east lead and tied down with a handbrake. Any hot cars were switched and positioned first out to be worked on the next day, while the balance of the rips were positioned behind these cars and everything shoved back clearing the road crossing. On occasions you may find a hot car setting under the hood on the east track, but this was rare. The repaired cars were pulled from the east lead and taken to the top of the hill and humped.

The inside of the shop complex consisted of four small cranes at each end of the east and west leads for handling heavy loads. Various jacks were used to move the car body off the trucks to replace wheels when necessary. There were various cutting torches and welding equipment located on two wheel trucks as well as wheel stands to be positioned under the car frame to protect the employees as they worked. Various types of small repair parts were located on shelves as well as containers of grease and oils stood as silent statues against the west wall and were ready available when needed. Replacement parts were located at various locations in front and on the side of the building on wooden pallets and were moved using the forklift. This was also used for moving wheels back and forth from the building to the wheel rack as well as moving freight cars when needed. The shop foreman's office was situated in a separate enclosed building outside of the repair area on the eastside as well as the employees changing room with lockers, restroom and eating area.

Once the repaired cars were humped the crew returned to the shop to finish up by working the dock and wheel track as indicated on the list. The Dock Track consisted of concrete dock with a ramp and was wide enough to handle a forklift moving pallets from boxcars from this location using the ramp as I stated earlier. This track could only handle one car at the dock, with storage room for one or two more. Many cars stayed at this location for long periods, until unloaded as they were usually company cars and were used for storage. The switch leading into this track and the wheel storage area came off the east lead and continued past the dock and alongside the eastside of the building next to Departure Track #4, where it ended at the wheel storage rack on the opposite side of the building. The problem switching this track it was centered in the middle of the service road and in the winter everything froze over the rails from auto and truck traffic by railroad employees. On these occasions the engine ran in first slowly breaking the ice, snow and mud. If the engine derailed we could usually back slowly and the wheels returned to the rails as the pathway made was frozen.

Cars containing wheels were painted gray with rails bolted to the deck with wheel chocks situated at end of the rail and handled various sizes of wheels from 28, 33, 36 inches. These wheels were pulled from this car with a forklift and chain, where they were set onto a wheel track. There were three or four tracks used for storage, with wheel chocks at the end of the track. Worn or defective wheels were returned back onto this car and were sent to the shops in Altoona, PA., where they were either turned or cut up for scrap. The Dock Track was usually switched every six or seven days, while the wheel car arrived usually once or sometimes twice a month depending on the situation. There were occasions where a semi flatbed truck would arrive with five or six wheels sets in emergency situations.

Enjoy the hobby and have fun.

Bar Mills Build Challenge Reveal - Part 2

We had 6 Bar Mills models shown during our March meeting. Each person showed what they had done and gave some insight on how the felt the kit went together. It was all very insightful.

Nancy Whitehill Earl's Oil Company (used as model within a G-Scale model) - HO Scale

Tony Kukwa Maintenance Shop at Cranberry Yard - HO Scale

Jeff Schumaker Staton Marine - HO Scale

Dave McMullian Office at Cranberry Yard - HO Scale

Steve Glass Rusty Radiator - HO Scale

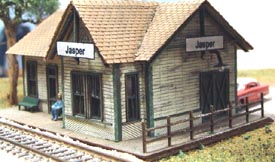

Jim West Whistlestop Junction (I missed photographing Jim's model so the Bar Mills version is shown) - N Scale

Division Happenings

The "BIG" event this last month was the Spring Modelers Meet we hosted at the Sylvania Senior Center. Although we got a fair number of accidental walk ins from the craft show next door, we have received a lot of positive feedback from the attendees. Unfortunately we were having so much fun that none of us realized we needed to get some photos of everyone having so much fun!!

One event that was captured was the tragic de-construction of some of the buildings on Steve Kellogg's module. As Steve puts it, the tragic event was "caused by my tripping over my own feet while loading them into the trailer". It did not take long for Steve to have the buildings and the module back together again as seen in the images below.

A box full of pieces after the "disassembly event".

The module showing the loss of the buildings and other damage.

An upside to having to rebuild a building, the ability to make an addition / improvement to it. Steve added a light over the stairs and a figure standing on the deck talking on her phone.

The YMCA is back. Maybe some more vines than before?

Train Order

Train Order